The Mhs - Material Handling Supply Inc. Ideas

The Mhs - Material Handling Supply Inc. Ideas

Blog Article

What Does Mhs - Material Handling Supply Inc. Mean?

Table of Contents8 Simple Techniques For Mhs - Material Handling Supply Inc.Fascination About Mhs - Material Handling Supply Inc.Our Mhs - Material Handling Supply Inc. StatementsMhs - Material Handling Supply Inc. Things To Know Before You Get ThisMhs - Material Handling Supply Inc. for DummiesEverything about Mhs - Material Handling Supply Inc.

This line is called the line of action. Forklift dealer. If the base of this line goes outside of the stability triangular because a lots is too heavy or too expensive, or because the forklift is out a degree surface it will topple. A vertical line prolonging from the facility of gravity of the vehicle-load combination should remain inside the stability triangle to stop the forklift from tippingThe various other concept to comprehend is the forklifts facility of gravity. When unloaded, the forklifts facility of gravity is appropriate about here.

Much heavier lots shift the center of mass ahead also further. Raising the load likewise changes the center of mass forward. In order to avoid the lift from tipping, the consolidated facility of gravity of the load and the lift need to remain inside the security triangular (at ground degree) at all times.

The Basic Principles Of Mhs - Material Handling Supply Inc.

If you have a balanced load, the load is unlikely to influence the side-to-side center of gravity. https://businesslistingplus.com/profile/mhsinc30677/. If you drive on a sloped surface area, your center of gravity could pass exterior of the security triangular and the lift might tip. Every forklift has a recognition plate that lists important info regarding the truck

To ensure that the center of mass of your forklift stays inside the stability triangle, don't try to lift anything heavier than the recognition plate permits. Regardless of just how active you are, you have to evaluate your forklift prior to utilizing it. If you do discover something that might affect the safety of the automobile you must report it promptly.

Comply with the operators handbooks provided by the devices maker. These handbooks explain the safe procedure and upkeep of forklifts. Keep in mind, the operator is responsible for the secure procedure of the forklift. Do a pre-operation examination prior to every shift. If the forklift is made use of all the time, check it either before each change or after each shift.

4 Simple Techniques For Mhs - Material Handling Supply Inc.

It is completed in two components: the walk-around inspection, and, the seated evaluation. OSHA does not call for documents of a daily assessment. It's a good idea to have a checklist to make certain you don't miss out on any kind of actions. These lists can also be saved as a part of the maintenance record.

If the forklift is an outdoor forklift with pneumatic tires, examine the air stress and look for extreme wear on the tires. A tire with reduced air stress might trigger the lift to tip when a tons is increased.

Some Known Questions About Mhs - Material Handling Supply Inc..

Examine the engine for any type of indicators of wear, loosened connections, or leakages. Look for fractures or deformities in the forks, back-rest, mast, and above guard. Check the identification plate to make certain it is intact and readable.

Constantly start the engine while seated in the driver's positionnever while standing together with the forklift. Inspect all determines and advising lights, and the battery or fuel level. Raise and reduce the forks, and tilt the pole.

What Does Mhs - Material Handling Supply Inc. Mean?

You'll need to sound the horn at intersections, and any place vision is obstructed. Check the brakes by depressing the brake pedal. There ought to be some resistance. Set and examine the car parking brake. Examine the guiding. A lot of play or hard steering will lower your control. Move the forklift onward a couple of feet.

Leakages can show a hydraulic issue, and liquids left on the flooring are a sliding danger. Look for stimulates or view website fires coming out of the exhaust system. Pay attention for any unusual noises. If you find anything wrong with the forklift during the walk-around or seated assessment, do not run it till it has been fixed.

Little Known Facts About Mhs - Material Handling Supply Inc..

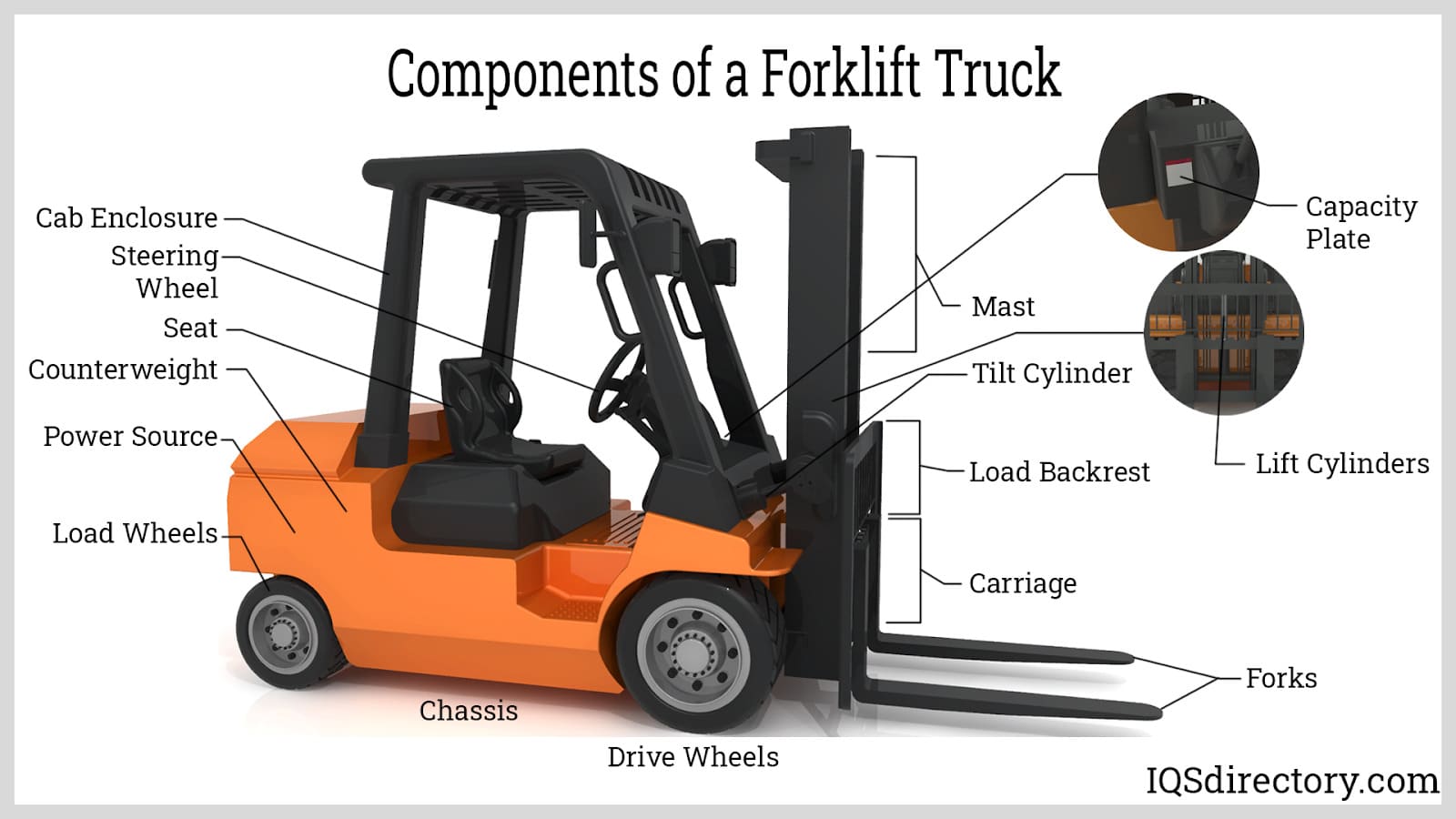

Forklifts have lots of relocating parts and items that enable the forklift to operate correctly. Understanding the terminology of the parts and composition of a forklift is essential for effective communication with others while on duty - https://disqus.com/by/tannergraves/about/. Here are some of the essential features and parts that compose the anatomy of a forklift vehicle

For many forklifts, the mast is designed toward the front of a forklift and straight in the forklift driver's field of vision. Forklift poles include different sections that boost or reduced the forklift carriage together with the forks. These include:: 2 mast stages: 3 mast phases: 4 mast areas When choosing a forklift, it is essential to familiarize yourself with the various functions and terminology of a forklift pole: the mast's lift elevation, the complimentary lift height and the extended elevation and the lowered elevation.

Report this page